Having an excellent grow environment is crucial for crops of all sizes. Your grow environment includes the walls and ceiling that surround your space. This environment is usually a building, a building’s interior room, or an indoor grow tent.

When designing buildings and interior rooms, it’s important to consider the grow space construction materials. This includes which types of walls to use, and/or what type of finish material to use. For smaller crop sizes, making use of a grow tent may also be an excellent solution. Here it is important to consider the overall design of the tent.

For Buildings and Interior Grow Rooms

The exterior walls for new or existing buildings will be made of the material or system used to create the building envelope and to support the roof. The grow spaces or grow rooms will be located just inside these exterior walls. What needs to be addressed are the interior finishes on these interior walls. Further, we should also consider the insulation value (resistance to temperature transfer).

These are three wall finishes suitable for grow room walls.

Gypsum Wallboard:

There are a few different names for gypsum wallboard, such as drywall, sheet rock, and Gyp. Board. This is a common material on existing buildings. However, usually the gyp. board on existing buildings is not the type suitable for grow environments.

The type of gyp. board most ideal and suitable is: “Type X gypsum board, moisture resistant.” The type x notation indicates that the gyp. board should be 1-hr fire rated. The thickness can be 1/2″ or 5/8″, with the later being more ideal for durability reasons. Additionally, the gyp. board will need to be painted with a moisture resistant paint.

Pros: Easy to install.

Cons: A few more steps involved in installation. Can be difficult to maintain over time. Does not offer insulation value on its own.

FRP panel (Fiber Reinforced Plastic):

Fiber Reinforced Plastic panels that are fastened directly over an existing gypsum wall board surface. For grow rooms, the FRP panels help to replace the pain and the need for a more upgraded gyp. board. The dimensions for FRP panels are typically 1/8″ thick; in 4’x8′ sheets. FRP panels provide good moisture resistance. Also, they come in a variety of colors and textures. These panels can be fastened directly over an existing gypsum wall board surface.

Pros: Easy to install. Low initial cost.

Cons: Can be difficult to maintain over time. Does not offer insulation value on its own. Cannot be used on ceilings.

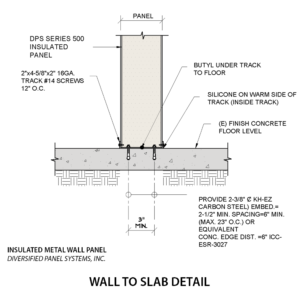

Insulated Metal Wall Panel:

Insulated metal wall panels are similar to a metal stud wall, but are also infilled with insulation and come with a finish surface. These panels come in a variety of different thicknesses, ranging from 2-12″ thickness. The panel widths are roughly 46″ wide, and the lengths can vary.

The insulated metal wall panels make installation of these panels similar to installing a metal stud wall. Each panel segment is pre-manufactured with foam insulation and a metal exterior finish. These wall panels can be installed just inside the exterior walls. The panels can also be used to construct the interior grow rooms, and secondary interior ceilings.

Pros: Quick to install. Medium initial cost. Easy to maintain. Can be used on ceilings.

Cons: Skill installation. Medium initial cost.

For Interior Grow Tents

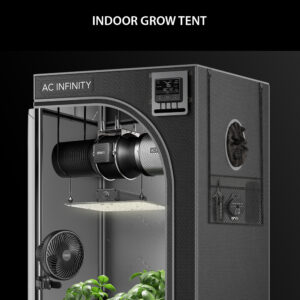

Interior grow tents work excellent for smaller crop sizes. These tents are easy to assemble and designed to help integrate other grow environment equipment.

Interior grow tents work excellent for smaller crop sizes. These tents are easy to assemble and designed to help integrate other grow environment equipment.

Some key features to consider when choosing a grow tent include: the material thickness/ durability, the frame construction, dimensions, and the built in openings.

The indoor grow tents are usually made of canvas type material. Most tents, also have a reflective coating on the inside surface. They come in multiple floor plan dimensions, ranging from 2’x2′, 2’x4′, 4’x6′, 5’x8′, etc.

Pros: Easy to assemble. Low initial cost. Moveable.

Cons: Not many. Space limitations for larger quantity grows.